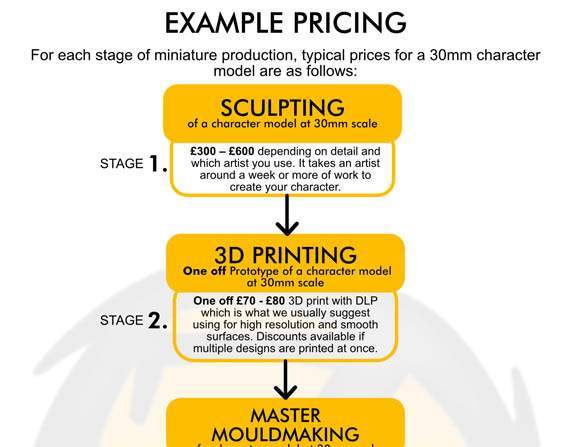

DLP Resin 3D Printing

At Zealot, we have a suite of DLP resin 3D Printers. DLP prototyping produces tough resin master prototypes at an affordable price. With layers down to 1 micron Z steps, we can provide prints for any application. We set up support structures by hand so that your part has the minimum amount of supports to be cleaned up. Combined with the supports contact point being typically 100 microns or below, your model is produced at the highest quality. XY accuracy down to +/- 13um (micron) yields sharp and smooth prints in all axis. We print in a range of materials, from off the shelf Envisiontec RC90 or heat resistant FusionGrey for vulcanised rubber moulds, even custom in-house blended resins. We will always recommend and print in the best material for your application.

DOD Wax Printing

DOD Wax Printing produces models in a fragile, yet equally detailed material to DLP resin prints. For applications where physical supports would be impossible and a model could not be printed with DLP printers; we would then recommend printing in wax. This is because DOD printing uses a melt away support material that allows complex geometries to be printed with no intrusion from support rods. DOD wax produces parts down to 6 micron Z layers. The liquid piezo crystal deposition delivers an XY DPI 8,000 x 5,000 DPI.

(Voodoworx Miniatures Printing) We would recommend our DOD printing for only specific models which require the support material. Since the costs of printing and the speed of printing are prohibitive. DOD wax printing is a slow process with a standard 28mm model taking upwards of 40 hours to prototype. Fragile thin parts like weapons spears, antenna may not be suitable for DOD wax printing.

FDM Plastic Printing

We also offer FDM printing for larger applications, test fitting, or for printing an armature of a model that can be traditionally sculpted over.

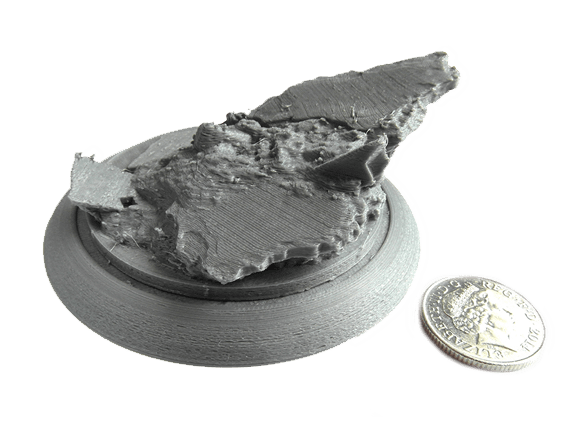

(Base “Armature” for traditional sculpting over. Mitches Military Models) FDM extrudes molten plastic and can produce resolutions down to 50 um (micron) Z layers. With a nozzle diameter of 400 um (microns). While layers are clearly visible on models and fine details is lost. FDM prints are cheap and fast which make them perfect for certain applications.

Resin Casting

We run a quality resin casting service to produce your range of miniatures in Polyurethane resin. Cast under both high vacuum and high pressure in a hybrid casting method, parts have superb detail and far less gates and sprues than other resin casting methods.

We aim to produce casts that cater for collectors and painters who are looking for quality miniatures that will stand out against the competition. As well as by working with our established partners such as MDC (http://www.modeldesignconstruction.co.uk) we can offer larger volumes of miniatures.

Digital Sculpting

We have over six years of experience in digital sculpting specifically for miniature production. Producing sculpts 100% suitable for production. We take on in-house design and sculpting projects or we can bring in sculpting services, both digital and putty, from our established network of freelancers.